PosWeTool project indirectly funded by the European Union through the Horizont 2020 research and innovation programme (Grant agreement no. 873087).

SMASP has been selected for the development of the PosWeTool project within the SHOP4CF call for proposals.

The aim of SHOP4CF

The new era of human-centred robotics in Europe, with easy-to-use, plug and play solutions.

Page SHOP4CF

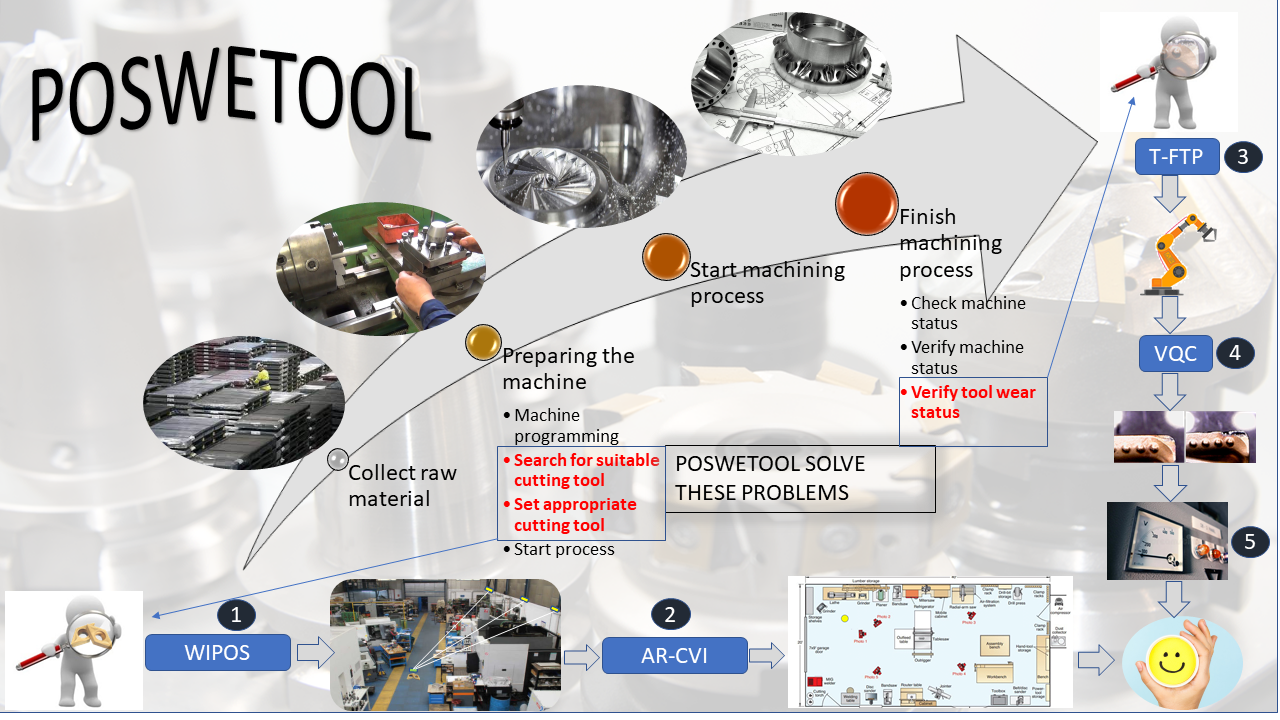

The problem

One of the main goals of manufacturing is to maximise production efficiency. Today, it is impossible for any company to risk being left behind in the huge transition to smart manufacturing.

More efficient and reliable asset tracking, which is the ability to locate and track equipment, tools and work in progress, leads to higher overall equipment effectiveness (OEE) and consequently more efficient operation of personnel, equipment and management of process inputs and output products. This leads to considerable operational savings.

The main objective of the present project is to apply ultra short web (UWB) positioning for tool positioning support and troubleshooting. And the application of image comparison algorithms to determine tool wear.

It is almost impossible to control the location of thousands of different cutting tools in the machining enterprise. Especially when some tools get mixed up or even lost and are required to be used urgently, bearing in mind that sometimes you have a limited number of tool types as they are not in common use.

Knowledge of the life cycle of tools is very important for stock control and the purchasing department. Tool wear monitoring will be digitally measured by Artificial Intelligence (AI) and also analysed by analysing the energy consumption of the machine.

An intelligent software will be developed that includes all the characteristic parameters of the tools, associated to the machines of their manufacturing process, the new tools in stock and the used ones; considering their wear conditions.

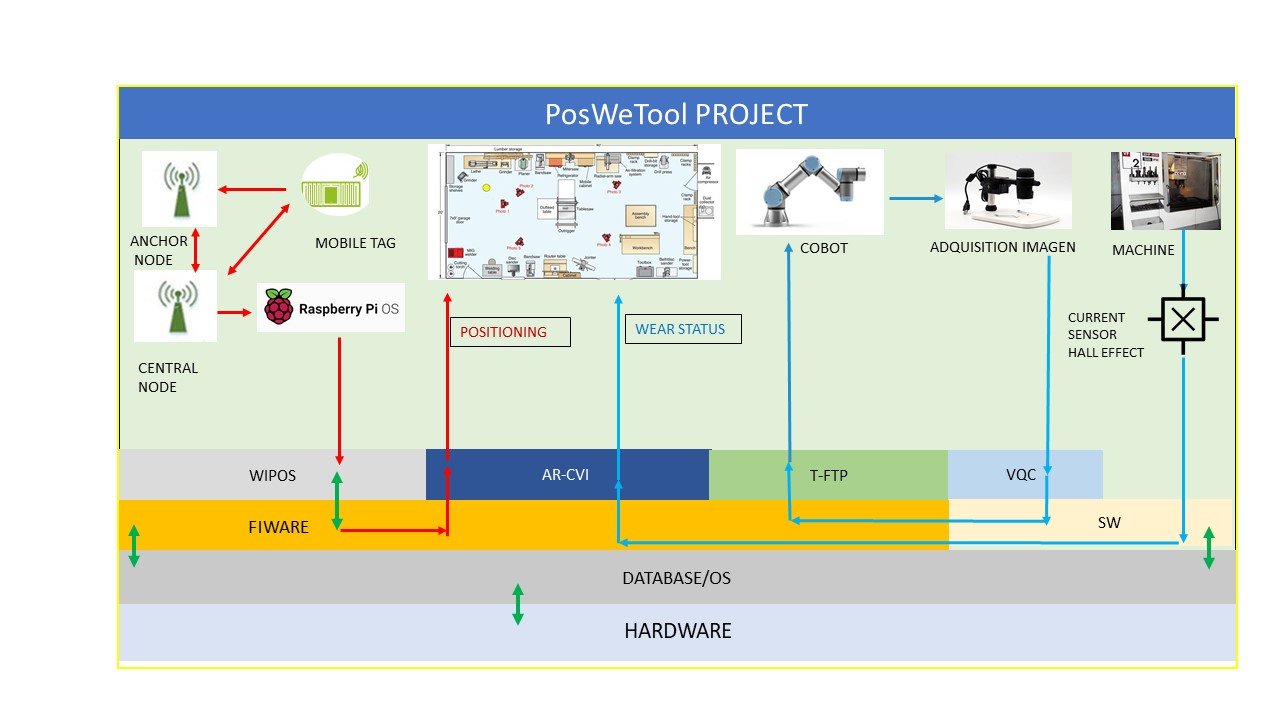

FIWARE conveys an advanced framework of open source software platform components, which can be assembled together and with other components developed to build platforms to make the development of intelligent solutions easier, faster and cheaper.

In manufacturing workshops, a large number of cutting tools are used on a daily basis. Production-conscious workers pay less attention to the placement of tools in the right place.

Some of these tools are new, others are reusable or may be completely worn out.

In manufacturing workshops it is necessary to know the state of wear of the tools, to decide whether to reuse or stop using them, as it depends on the quality of the manufactured part, and to plan a stock of spare tools to be able to continue manufacturing.

To solve these problems, the PosWeTool project was created.

The project PosWeTool

The main function of PosWeTool is to identify the position of the cutting tools in the machine shop in the workspace and to show the status of each cutting tool, whether it is new or used; with its level of wear, on the other hand.

For the development of PosWeTool, different technologies will be applied, depending on the objective to be achieved.

To determine the positioning of the tool, UWB technology will be implemented and, on the other hand, to know the state of the tool, with its level of gradual wear, especially for used tools, image recognition technology will be placed, by means of a digital camera, in a Cobot to perform a 360º visual inspection of the cutting tool in order to carry out a visual inspection and tool wear measurements.

In addition, the energy consumption of the machine will be extracted and associated with the state of deterioration of the cutting tool. The PosWeTool project consists of two main functional blocks:

- Intelligent software development: this includes the cutting tool database, artificial intelligence algorithms, middelware and the graphical user interface to interact with the user, transmit information and make the system intelligent.

- Technological evolution: will comprise two approaches:

- Tool positioning: it will be realised by integrating the SHOP4CF components; WI-POS to perform the positioning and AR-CVI to show it through a project the positioning of the tool in the factory layout.

- Tool wear: this will be carried out using the components; VQC, which will compare the images of a new tool with the current one, and AR-CVI which will show the results.

| The POSWETOOL project has received funding from the European Union’s Horizon 2020 research and innovation programme under grant agreement No 873087. Neither the European Commission (EC) nor any person acting on behalf of the Commission is responsible for how the following information is used. The views expressed in this publication are the sole responsibility of the authors and do not necessarily reflect the views of the EC. |  |

|---|